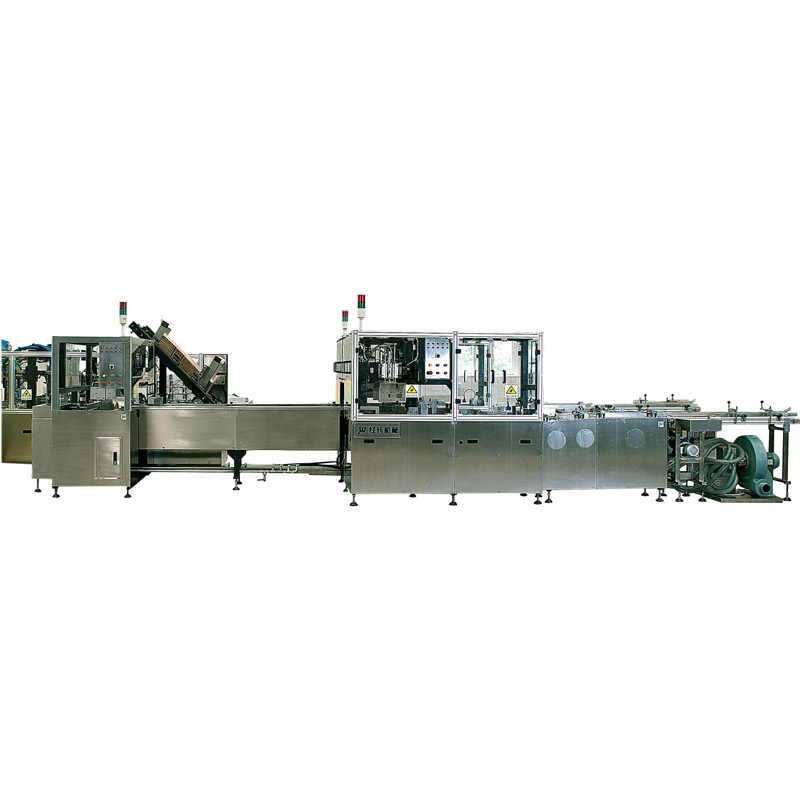

I-Automatic Bag Noodle Case Packer-ZJ-QZJ20

| Amandla okukhiqiza | 18 amacala/min (24 imizila) |

| Isiteshi | Isiteshi se-Encasement: 11;Ubude besiteshi: 571.5 mm, Isiteshi sokuthutha: 16;Ubude besiteshi: 533.4 mm |

| Usayizi webhokisi | L: 320-450mm, W: 320-380mm, H: 100-160mm |

| Amandla omshini wokuncibilikisa iglue | 5KW |

| Amandla | 15kw, ulayini wesigaba sesihlanu, AC380V, 50HZ |

| Umoya ocindezelwe | 0.4-0.6Mpa, 700NL/min (ubukhulu) |

| Ubukhulu bomshini | (L)10500mm x(W)3200mm x(H)2000mm (Ungafaki isihambisi sokungena) |

| Ubude bokukhishwa kwebhokisi | 800mm±50mm |

Izici

1. Ukusebenza okulula, ukuphatha, ukuncishiswa komqhubi kanye nomfutho wabasebenzi, kanye nokuthuthukiswa kokusebenza kahle komsebenzi.

2. Umshini unokusebenza okuzinzile nokuthembekile, ukuhlelwa okuzenzakalelayo nokuvaleka kahle kwebhokisi kanye nezici zobuciko ngokushelelayo.

3. Ifaneleka ngokukhethekile ukufanisa nomugqa wokuhlanganisa wokupakisha ukuze uthole ukukhiqizwa nokupakisha okuzenzakalelayo ngokugcwele.

Ilungele ukupakishwa okuzenzakalelayo kwama-noodle asheshayo nama-noodle asheshayo.

Nansi eminye yemisebenzi yokuqonda:

I-Bag Infeed: Lesi indawo yokuqala yomshini lapho ama-noodle afakwe esikhwameni elayishwa ku-conveyor.Izikhwama zivame ukugcwaliswa ngaphambili ngama-noodle futhi zivalwe.

Ukuvula Isikhwama: Izikhwama zibe sezivulwa kusetshenziswa isivuli sesikhwama esisebenzisa izinkomishi zokumunca ukuze sibambe isikhwama futhi sisivule, sivumele ama-noodle aphume.

I-Carton Erecting: Umshini ube usubeka amabhokisi bese uwamisa ukuze agcwaliswe.Amabhokisi avamise ukupakishwa ngesicaba ngaphambi kokuthi alayishwe emshinini.

Ukugcwalisa: Izikhwama ezivuliwe zama-noodle zibe sezigcwaliswa emakhathoni kusetshenziswa uhlelo lokugcwalisa.Isistimu isebenzisa uchungechunge lwamabhande, amafaneli, nama-chute ukuze iqondise ama-noodle ebhokisini.

Ukuvala Ikhathoni: Uma amabhokisi esegcwalisiwe, ama-flaps asongwa phansi

Ukudlulisa Ikhathoni: Amabhokisi abe esehanjiswa esiteshini esilandelayo ukuze aqhubeke nokusebenza.

Ukulawula Ikhwalithi: Kulesi sigaba, amabhokisi ahlolelwa ukuvaleka okufanele kanye nesisindo esilungile se-noodle.

Ukupakishwa Kwebhokisi: Amakhathoni agcwalisiwe futhi avaliwe abe esepakishwa kuma-pallets ukulungiselela ukuthunyelwa.

Uhlelo Lokulawula: Yonke inqubo ilawulwa isilawuli se-logical logic (PLC), esiqapha futhi silawule izingxenye ezihlukahlukene zomshini.

Sekukonke, umshini ozenzakalelayo wesikhwama sebhokisi le-noodle wesikhwama uyindlela ephumelelayo nethembekile yokupakisha ama-noodle afakwe emaphaketheni emakhathoni.Umshini uyakwazi ukuphatha ivolumu ephezulu yama-noodle futhi ungawapakisha ngokushesha nangokunembile.Kuwucezu lwesisetshenziswa esibalulekile sabakhiqizi bokudla abadinga ukupakisha imikhiqizo yabo ngendlela engabizi futhi ephumelelayo.